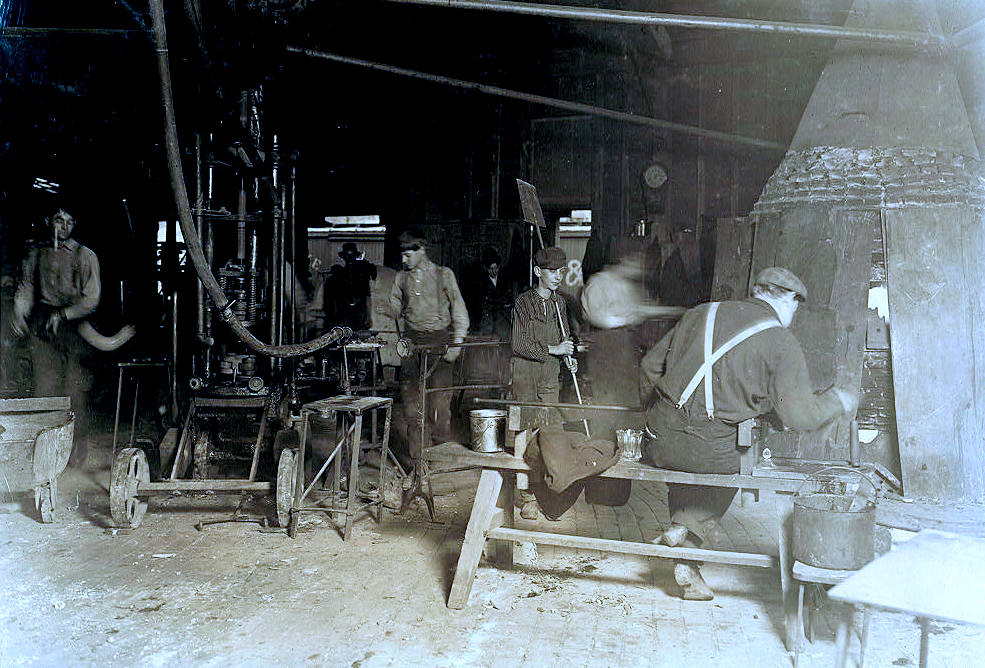

In 1903, an American glass factory worker named Owens revolutionized the industry by inventing a machine that automated glass bottle production. Before his invention, a team of six workers could produce 2,880 bottles in a 24-hour shift. With his machine, only two workers were needed to produce a staggering 17,280 bottles in the same timeframe. This innovation slashed manufacturing costs from $1.80 per bottle to just 12 cents. While the widespread adoption of glass-making machines significantly reduced the number of skilled artisans, such as Venetian glassmakers, by nearly half, it also led to the eradication of child labor in glass factories.

The industrial automation wave had already begun centuries earlier. The 17th-century Industrial Revolution marked a turning point, paving the way for mechanized production. British inventor Oliver Evans’ automated flour mill rendered traditional European windmills obsolete, reducing them to tourist attractions. By the 1920s, the advent of electricity and the Ford production system completely transformed factory operations. Struggling with labor shortages after World War II, Ford Motor Company introduced conveyor belts and mechanical arms—coining the term “automation” to describe this new era of manufacturing.

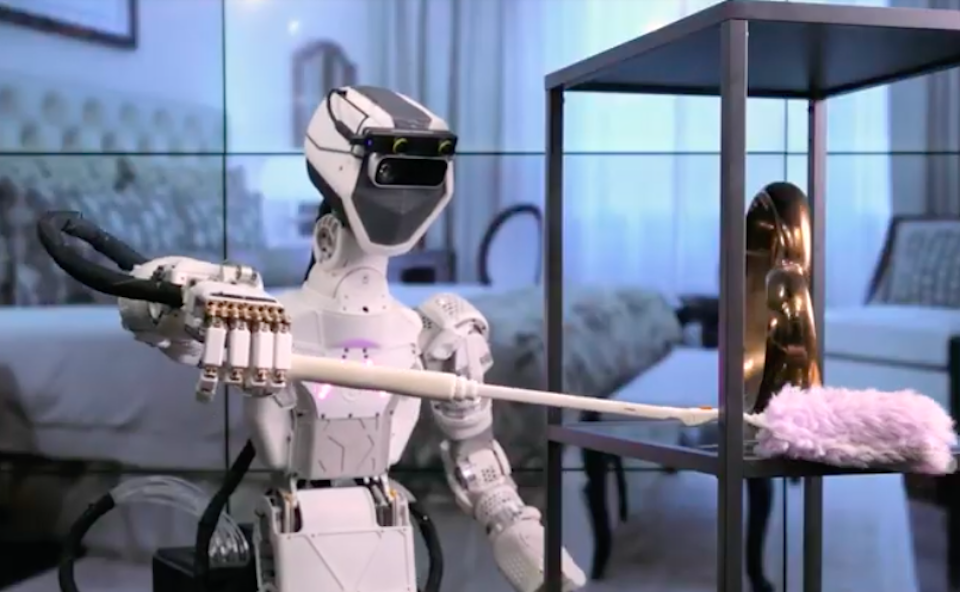

Then came the era of computerized precision control, prompting management guru Peter Drucker to observe, “For the first time in human history, machines are operating other machines.” Among robotics engineers, a popular joke emerged: “The factory of the future will need just one human and one dog. The human’s job will be to feed the dog, and the dog’s job will be to ensure the human doesn’t interfere with the machines.” But with the rapid advancements in artificial intelligence (AI) and humanoid robotics, this scenario is no longer just a joke—it is fast becoming reality.

These days, some of the most viral stories in the industrial sector revolve around tech giants showcasing their humanoid robots’ incredible feats. Tesla’s humanoid robot has demonstrated the ability to catch a thrown tennis ball, while China’s Unitree Robotics has unveiled robots performing backflips. Boston Dynamics, a subsidiary of Hyundai, has exhibited robots executing acrobatic rolls and handstands. Meanwhile, Norwegian engineers have created robots that can carry laundry baskets and operate vacuum cleaners. Tesla and Hyundai have already announced plans to integrate humanoid robots into their vehicle assembly lines.

The long-theorized “one human, one dog factory” may soon be a reality. Thanks to AI, humanoid robotics, and the Internet of Things (IoT), fully automated “dark factories”—factories that require no human presence—are emerging. These facilities need no lighting, rest areas, cafeterias, or climate control, drastically reducing operational costs. Chinese tech giant Xiaomi has already established such a factory, where cutting-edge smartphones roll off the production line at a rate of one per second in complete darkness. The pace of technological advancement is nothing short of astonishing.

But as dark factories become the norm, a pressing question looms: Is this evolution a boon for humanity or a looming catastrophe? The answer remains to be seen as we navigate this unprecedented era of automation and artificial intelligence.

https://www.instagram.com/spectacular/reel/DGlpY2WuwRg/?hl=en